OARC’s Research Data and Web Platforms group partnered with CESMII to ensure that CESMII’s Smart Manufacturing Innovation Platform (SMIP) could withstand the needs of small- and medium-sized manufacturers.

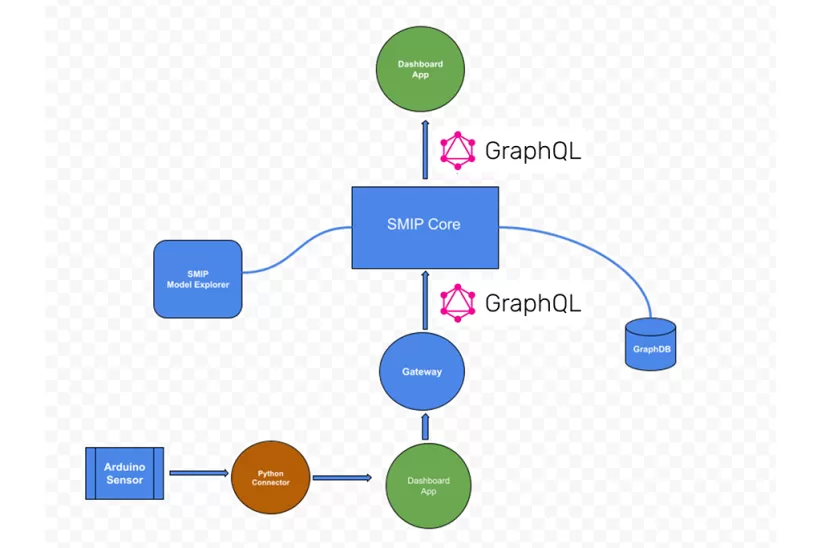

To conduct the pressure testing, the group performed three discrete, progressive tasks that used commercially available edge appliances and sensors to model the path a manufacturer with both limited resources and limited digital readiness might undertake to begin using the CESMII ecosystem. Specifically, the group outfitted an Arduino single-board computer with temperature and humidity sensors and then programmed it to send data to the SMIP for processing. The processed data was then output to a dashboard to simulate the experience a line worker in a factory might have in a decision making context.

The CESMII SMIP is part of an ecosystem for Smart Manufacturing that includes a marketplace for applications; a data contextualization engine; a Profile Designer for the creation of structured, reusable information models; and GraphQL connectors that facilitate communication across the different components of the ecosystem.

As a result of the pressure test, the Research Data and Web Platforms group found the CESMII SMIP to have sufficiently low barriers-to-entry for companies just beginning their digital journey by way of available freeware and open source tools. They also uncovered opportunities for growth in areas of online documentation, open source code snippets, and synchronized update schedules and created a strategy to extend the testing on a larger scale in an industrialized setting for an opportunity to gather more data and make improvements.